- Show results for

- Share

How to Enhance Industrial Security: a Focus on Lockout & Tagout

Resource Description

Contents

- What Is LOTO?

- What Are The Forms of Energy?

- What Is The Difference Between Lockout And Tagout?

- What Are The Advantages and Challenges Of Lockout/Tagout?

- What Are The Main Steps Of A Successful LOTO Program?

- What Are The Most Common Lockout/Tagout Mistakes?

- Lockout Stations And Kits

- What Are The OSHA Lockout/Tagout Requirements?

Different types of equipment in many industries store energy. Its unexpected release or accidental equipment start-up may cause a hazard to workers. However, there is a way to control energy and keep employees safe.

What Is LOTO?

The abbreviation "LOTO" stands for the lockout/tagout procedure, which is used at facilities during equipment maintenance or repair. LOTO includes specific measures to control hazardous energy and thus provide safety. The set of LOTO measures is aimed at the prevention of injuries or deaths because of an accidental or unexpected equipment start-up. LOTO is one of the most critical OSHA standards.

Lockout/tagout includes the use of many products:

- lockout padlocks;

- hasps;

- tags;

- labels;

- signs;

- toolboxes & cabinets and more.

Popular Products

There are also handbooks and posters to provide employees with all the necessary information.

Enterprises that fail to follow specific rules to recognize and control machine hazards face the risk of serious accidents as well as regulatory fines. Safety rules must be followed and workers will be protected from unwanted hazards.

What Are The Forms of Energy?

The main threat usually comes from a variety of energy forms that can be found at facilities – mechanical, electrical, pneumatic, thermal, hydraulic, and chemical.

Examples of hazards:

- ultraviolet light;

- moving chains or presses;

- conveyor belts;

- blades;

- propellers;

- hot fluids;

- electrical heaters.

Various forms of energy allow for the proper performance and operation of mechanisms and equipment. But these can also cause electric shocks, burns, and so on. The statistics on accidents are sad – each year about 50,000 workers get injured and 120 die on account of not following the lockout/tagout program or its absence. So, one of the main tasks of the employer is to train the employees to follow the LOTO program.

What Is The Difference Between Lockout And Tagout?

According to OSHA, Safety Lockout and Tagout Methods are required to protect workers from being injured which may happen because of the unexpected discharge of energy or start-up of the machinery. Lockout and tagout work differently. Let’s consider them a bit closer.

LOCKOUT VS TAGOUT

LOCKOUT | TAGOUT |

|

|

AIM: to isolate hazardous energy. | AIM: to warn and provide info about the ongoing service on equipment/machinery. |

Lockout devices are designed to hold an energy-isolating device (a mechanical device that physically prevents energy transmission/release) in a safe (off) position. Lockout products ensure protection as they prevent machines from energizing. How is it achieved? It’s all because lockout devices can’t be removed without a key or other mechanism or method for unlocking. | Tagout devices are considered to be warning devices. An authorized employee (the one responsible for lockout/tagout) fastens them to energy-isolating equipment in order to warn employees not to re-energize machines when there is equipment service or inspection. Please note that a tagout device is easier to remove and it offers no physical protection compared to lockout solutions. |

Lockout includes fastening/attaching special lockout padlocks, hasps, etc. to power switches, valves, levers, and so on. | Tagout includes attaching “warning”, “danger”, “caution”, “notice” etc. tags or individual notes and more to specific energy switches/equipment. |

So, the difference between lockout and tagout devices lies in their function. A lockout device physically prevents a piece of equipment from energizing, while tagout devices are only designed for warning. In most cases, both lockout & tagout methods are applied.

What Are The Advantages and Challenges Of Lockout/Tagout?

Let’s consider the benefits and challenges of lockout/tagout.

ADVANTAGES

The employees are protected from the risk of hazards.

If everything is done properly and all the LOTO rules are followed, lockout/tagout can save people’s health and even lives, by preventing injuries. Dangerous situations can occur if the machine accidentally starts or if there is an unexpected release of hazardous energy, for example, arc flash, corrosive chemicals, steam blasts, etc.

The equipment and the workplace are protected from damage.

All the LOTO procedures must be followed to ensure that people are provided with a safe workplace and also to avoid damage to the machinery.

The costs are cut.

The lost time of employees and insurance costs are decreased. It can save companies a lot of money.

CHALLENGES

Inappropriate training.

Interactive training must be applied to all employees involved or affected by the LOTO process. The workers must know the theory and also know what to do for lockout/tagout. A lack of knowledge can lead to risks. For example, some people may be confused and think that a tag by itself on the equipment provides safety, but it doesn’t (tags don’t provide physical restraint like lockout devices). Then, such workers’ health/lives can be at risk.

Not following the lockout/tagout procedure.

Lockout/tagout requirements must be followed to avoid injuries and fatal consequences of incorrect actions.

Lack of specific procedures.

Specific procedures must be written and followed for each piece of equipment.

No timely audits.

LOTO procedures must be audited annually. The drawbacks of the lockout/tagout program must be removed, the procedure must be updated.

What Are The Main Steps Of A Successful LOTO Program?

Lockout and tagout measures represent the most reliable way of ensuring the safety of workers and preventing fatal consequences for their health and lives. Of course, when it comes to lockout/tagout, specific actions differ depending on the equipment and facility. However, there are a few basic steps:

1. Notification of Employees

Announcing the start of the LOTO procedure represents the first step. When it’s decided that a shutdown of equipment/machines must occur, all the employees who will be affected by the shutdown must be notified by authorized personnel. It’s important that all employees know that equipment will be shut down & locked out before maintenance.

2. Preparation, Energy Type & Magnitude Identification

An authorized person must refer to the lockout/tagout procedure to identify the equipment/machine that requires lockout/tagout, the energy sources (including energy magnitude) that are present and must be controlled, and the lockout/tagout devices that will be used. All required lockout/tagout devices (e.g. padlocks, tags, etc.) should be gathered.

3. Equipment Shutdown

The operating machines/equipment must be shut down. How can it be achieved? By pushing the Stop button, switching Off, closing a valve, etc. Shutdowns are important to avoid risks that can occur if the machinery stops unpredictably.

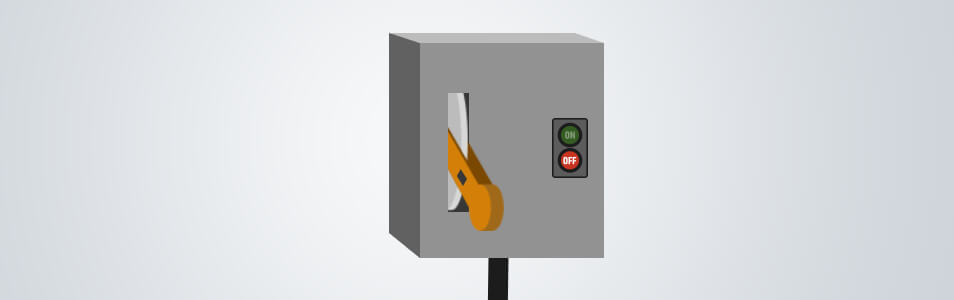

4. Equipment Isolation From The Energy Source

The machinery must be isolated from the energy source by using special energy-isolating devices (for example, a main disconnect switch or a line valve).

They must physically prevent energy transmission. Pay attention that regular On/Off and Stop buttons on a piece of equipment are not considered energy-isolating devices.

5. The Application of Lockout/Tagout Devices

Lockout/tagout prevents accidental start-up of equipment or its manipulation. There are two substeps: lockout and tagout. Let’s consider each one of them.

5.1. Lockout

Lockout devices are used to hold the energy-isolating device in a safe/off position.

A safety padlock, for instance, prevents the removal of the energy-isolating device so that energy can’t flow from its source to the equipment. An authorized employee attaches a lockout device (e.g. a lockout padlock) in a way that the equipment is in an Off (Closed) position and can’t be moved or switched on to an On (Unsafe) position. Note that all keys must be removed from lockout padlocks and kept with the person who applied the padlock.

5.2. Tagout

Tagout devices are designed to inform employees that the machinery may not be used until the tag is removed. A tagout device must be securely fastened to the isolating device so that it can’t be accidentally detached.

An authorized employee adds a lockout tag (e.g. Master Lock S4801), which must include the name and contact information of the authorized person who performs lockout/tagout actions.

In most cases, both lockout and tagout devices are applied:

6. Stored Energy Check

When all the energy-isolating devices are locked out, there should be a check for stored energy. Note that stored energy must be released or restrained after equipment has been de-energized.

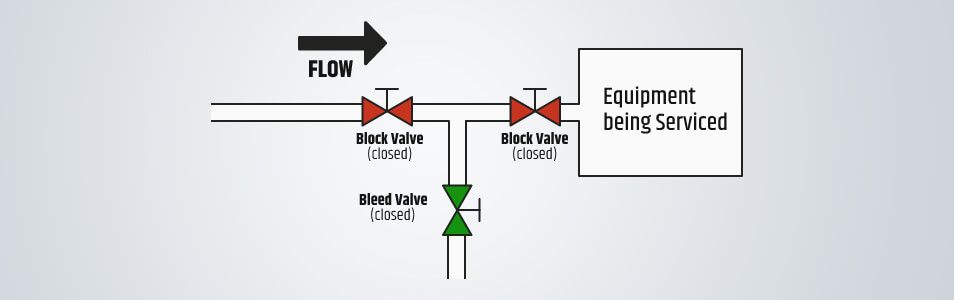

All residual energy (like in springs, capacitors, rotating flywheels, etc.) must be either dissipated or restrained from the machinery in order to ensure that it’s in a controlled state. It can be achieved by draining pressurized fluids, discharging electrical capacitors, releasing tensioned springs, and so on. Here’s an example of a double block and bleed system

It requires closing 2 in-line block valves and opening 1 bleed valve.

There must be no residual energy in a system.

7. Isolation Verification

When all the steps mentioned above are implemented, the one who is responsible for the procedure of lockout/tagout must check the equipment or system and make sure it is turned off and won’t accidentally start up. The system should be tested to ensure that energy isolation was successful.

This step is extremely important as it can even save people’s lives.

In order to verify that the machine is disconnected from the energy source, it should be tested. First of all, no employee should be exposed to the threat of any energy hazard. Then, the isolation should be verified by trying to operate it. For example, an authorized employee can push the On button for it. Then, after verifying isolation, the Off button should be pressed. Now you can be sure that the equipment is locked out and ready for maintenance or servicing.

8. Removing Lockout/Tagout Devices & Bringing Equipment Back For Work

Once the equipment has been repaired or serviced, the next step is to get the workplace and employees ready for work. Note that the steps must be followed in the correct order. Authorized employees must:

- Ensure that the equipment/machine is completely reassembled (e.g. check if guards and safety devices are reinstalled, if access panels are closed). The tools must be removed from the work area.

- Check the work area, all employees must be in a safe spot.

- Make sure that all controls are in a neutral position.

- Remove tagout & lockout devices in the opposite order in which they were installed. It should be done by the same authorized employee who applied them.

- Re-energize the equipment (note that some forms of blocking require equipment re-energizing before safe removal).

- Notify affected employees that the maintenance or servicing is done, the equipment is re-energized and they can use it.

What Are The Most Common Lockout/Tagout Mistakes?

To do everything the right way, the LOTO procedure must be followed. Otherwise, lockout/tagout won’t be effective and put people’s health and lives at risk. When performing lockout/tagout, employees can make mistakes. Let’s consider some of them so that you can avoid them.

Mistake 1 An authorized employee thinks that the lockout/tagout is not necessary as the maintenance/repair won’t take long. It’s not permissible. It doesn’t matter how much time you need for the equipment maintenance, it must be locked out/tagged out before that. Just shutting down the equipment is NOT enough. | Mistake 2 Incorrect use of tags & locks. All tags must be used for their intended purpose. Wrong tags may mislead workers and they can be injured as a result because of the wrong information on the tag. The locks that are intended for the lockout of the equipment shouldn’t be used for locking a toolbox or a cabinet, for example. It can degrade the importance of the lockout device. |

Mistake 3 The keys are left in the lock while performing the lockout procedure. In this case, anyone can remove the lock and then some workers may suffer from that. All the keys must be removed from the locks. Only then one can move on to the next step of the LOTO procedure. | Mistake 4 The application and removal of the same lockout/tagout devices are made by different people. It is recommended that the person who applied the lock/tag removes it when the maintenance is done. Otherwise, confusion may occur, someone may not do everything properly and as a result, the workers’ lives are at risk. In case this person is absent, the lockout device may be removed without an authorized employee who applied the lock but only with their approval and if the person who is going to remove the lockout device is trained to do so. |

Mistake 5 Not following machine-specific procedures. For every piece of equipment, there must be specific procedures that identify all energy sources as well as energy isolation devices. Note that all energy sources must be under control prior to any maintenance or servicing. In addition, there should be specific lockout devices for every machine. | Mistake 6 Not identifying all energy sources. When applying locks/tags, all energy sources must be identified. The most overlooked energy sources include gravity & kinetic energy, separate circuits running to a machine, etc. |

Mistake 7 An authorized employee doesn’t test the controls after the lockout procedure. Once the locks are applied, it is necessary to test the controls. The power must be totally removed. | |

Lockout Stations And Kits

The most convenient and efficient way to store all the necessary devices for a successful LOTO procedure is a lockout toolbox – a durable case that can accommodate devices that are needed for lockout/tagout, ensuring order and proper access to all the essentials. On our website, there are lockout toolboxes of various sizes available: bigger ones (e.g. Master Lock S1023), medium-sized (e.g. Brady 105906 or Master Lock S1017) as well as smaller toolboxes for lockout/tagout (e.g. Brady 105905).

You can also pay attention to lockout/tagout kits. For example, Brady Lockout Kit 134035 includes premium lockout/tagout devices designed to address electrical risks. Another great solution is NMC Valve Lockout Kit VLOK1. It has everything necessary for an effective valve lockout/tagout procedure.

Other variants are wall-mounted or portable lockout stations that contain a set of devices for LOTO.

Lockout/tagout padlocks, hasps, and tags are the essential elements of a proper LOTO procedure. For example, employees can apply steel or plastic hasps, lockout padlocks with safety information tags that will draw attention, and communicate vital information.

Different energy sources require various LOTO devices that have only two main features in common: reliability and bright color to increase visibility. However, there are no universal devices. For instance, when you deal with the isolation of a valve, you can make use of a specifically designed device. For example, Master Lock 485 is a rotating gate valve lockout device combo pack with lockout devices that feature outward/inward rotation for easy installation. In case you need to handle LOTO on a circuit breaker, you might need a snap-on or a clamp-on Lockout device (e.g. Brady 65688) – it will grab the employees’ attention and restrict access to prevent machine operation during maintenance.

What Are The OSHA Lockout /Tagout Requirements?

The OSHA standard lockout/tagout requirements are applied for regulating hazardous energy (pressure, electricity, and so on). This regulation requires following a specific program to perform the lockout/tagout procedure if there is a need for equipment maintenance or repair. Note that all steps of the LOTO procedure must be completed in a certain order, and all the instructions written in the lockout/tagout program must be followed.

Now, let’s consider a few basic lockout/tagout requirements:

- An employer must develop, implement, as well as enforce an energy control program.

- Equipment (whether it is all-new or overhauled) must be capable of being locked out.

- Lockout devices must be used for the equipment that can be locked out. Note that tagout devices can be used instead of lockout devices ONLY if in the tagout program, there is an equivalent to that provided through a lockout program.

- A tagout program must be developed, implemented, and enforced for the equipment that can’t be locked out.

- Lockout/tagout devices must be authorized for the particular piece of equipment, these devices must be: a) durable, b) substantial, and c) standardized.

- A lockout/tagout device must identify the individual user.

- Employers must provide their employees with special training so that they can perform the LOTO procedure. Such employees must include those who work on the equipment or around it. It is important that all affected employees understand the procedures of hazardous energy control. The workers must know the energy control plan, their position role as well as their responsibilities within this plan. It is necessary that affected and authorized employees know the OSHA LOTO requirements.

- Energy control procedures must be inspected at least once a year.

- One more requirement is to comply with the additional energy control provisions in OSHA standards.

Each industrial facility has its policy concerning the Lockout and Tagout procedure, which should be followed and audited annually. But there are also general requirements and standards represented by OSHA that must be followed by both employers and employees.